Tecsol, the metal works division of TecnoConverting, replaces sludge and biogas piping at one of Central Catalonia’s largest WWTPs

posted in News

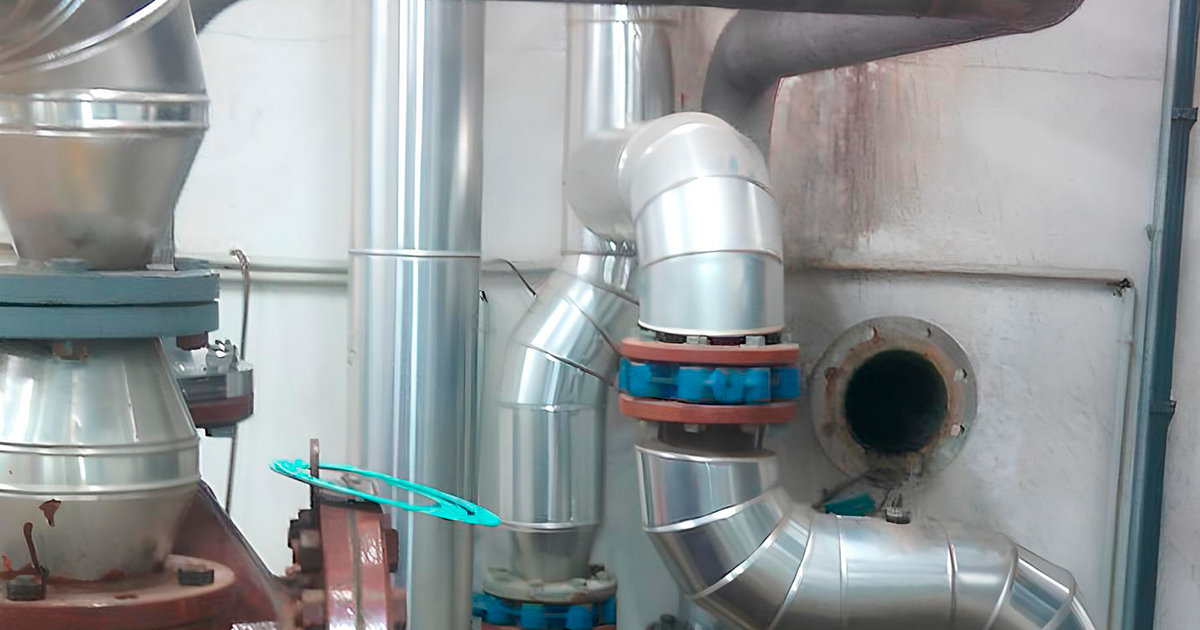

The sludge and biogas piping replacement at one of the largest WWTPs in Central Catalonia has been carried out by Tecsol, TecnoConverting’s metalworks division. Sludge recirculation and purge pipelines, as well as biogas lines, have been renewed entirely in stainless steel.

The main challenge of this project was the hazardous nature of removing old pipes due to the potential accumulation of gases inside the lines caused by sludge decomposition, and the high flammability of biogas piping, which can contain methane concentrations above 50%.

In broad terms, biogas is produced by fermentation bacteria responsible for breaking down organic waste (sludge) in the absence of air.

- Full stainless steel replacement: sludge recirculation and purge piping, as well as biogas lines.

- Controlled-risk intervention: safe removal considering potential gas accumulation.

- Cogeneration system: biogas used to produce electrical and thermal energy.

- No process shutdown: continuous work completed in the shortest possible time.

Initially, the biogas generated at this plant was only used to heat the digestion process and mix the sludge. Any excess gas was burned in a flare to avoid direct methane emissions into the atmosphere.

In recent years, the WWTP has implemented a cogeneration system, where all biogas produced is used to generate part of the electricity consumed by the plant itself.

In addition to electrical energy, cogeneration also produces thermal energy, which is used to heat the sludge in the digesters and increase biogas production.

Since the WWTP processes cannot be stopped at any time, all works involving sludge recirculation piping had to be carried out continuously and within the shortest possible timeframe to avoid interfering with the treatment stages.

Tecsol successfully met this challenge thanks to the adaptability and commitment of its highly skilled technicians, always aligned with the customer’s operational needs.

Do you need metalworks services or sludge and biogas piping replacement for your WWTP? Our team can provide technical support for your specific installation.