Effluent treatment for a desalination plant in Oman

posted in News by TecnoConverting

TecnoConverting has designed, manufactured and supplied the lamellar coagulation-flocculation and decanting units for the treatment of effluents in a project for a desalination plant (36.000 m3/d) and a combined cycle plant (183+25 MW) in Duqm (Oman). The units supplied correspond to 2 treatment lines for an average flow rate of 115 m3/h each, with the option of being able to treat in one of them up to a total flow rate of 230 m/h.

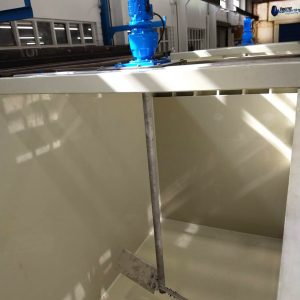

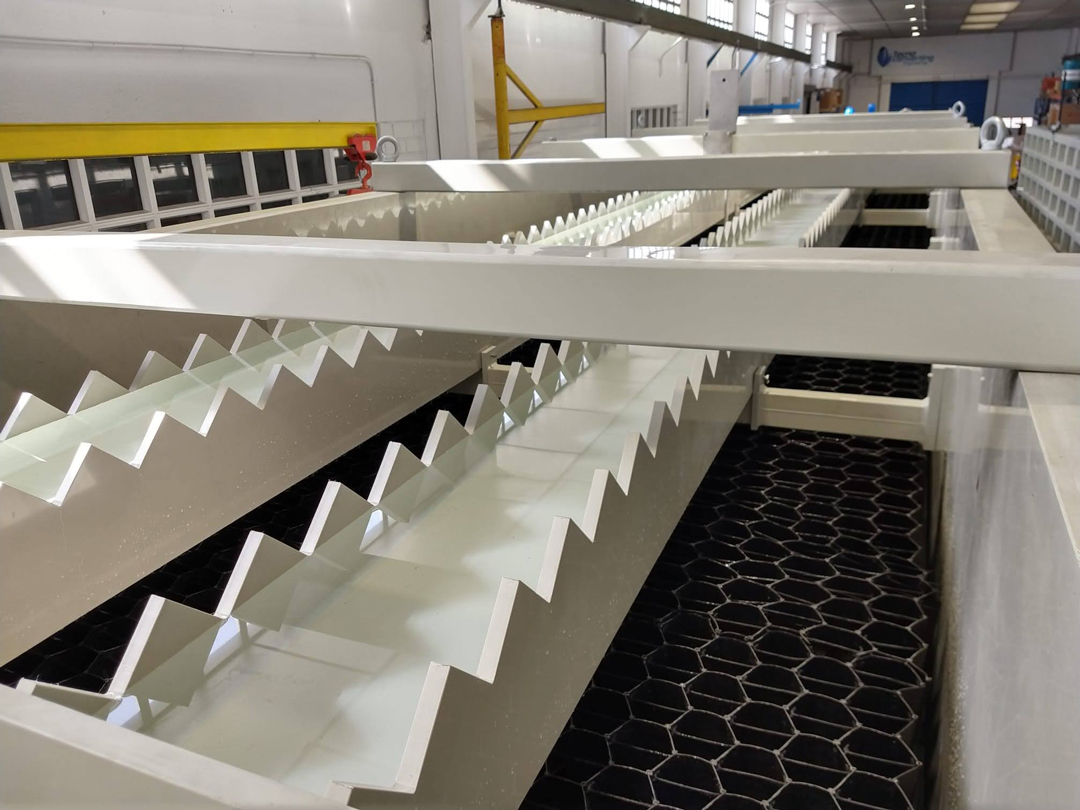

Each line is integrated by a coagulation-flocculation tank and a lamellar decanter which has been built in PPH to prevent corrosion from the high salinity of the water to be treated, with an external structure of C5M painted carbon steel.

The coagulation-flocculation tanks have been tailor-made and calculated based on the data provided by the client, where each chamber has a vertical stirrer installed, fast speed in the case of the coagulation chamber and slow speed for the flocculation chambers, along with a shaft and propellers in superduplex stainless steel.

For compact lamellar decanting units, each unit has an ultrasonic meter to control the sludge mantle level and pneumatic sleeve valves have been installed at each of the 4 sludge purge points available in each decanter.

The supply also included 2 sets of a walkway and inclined access ladder built entirely in PRFV to facilitate the maintenance and operational control of the units, as well as a PP boiler for the hydraulic connection of the units and the electrical connections of the mechanical equipment and instrumentation.