TecnoConverting Engineering supplies the physicochemical treatment tanks for the residual effluent treatment to a seawater desalination plant at the United Arab Emirates.

posted in News by TecnoConverting

TecnoConverting Engineering designed and manufactured the physicochemical treatment tanks for the residual effluent treatment to a seawater desalination plant at the United Arab Emirates, composed of two (2) parallel water lines, with a total treatment capacity of 200 m³/h.

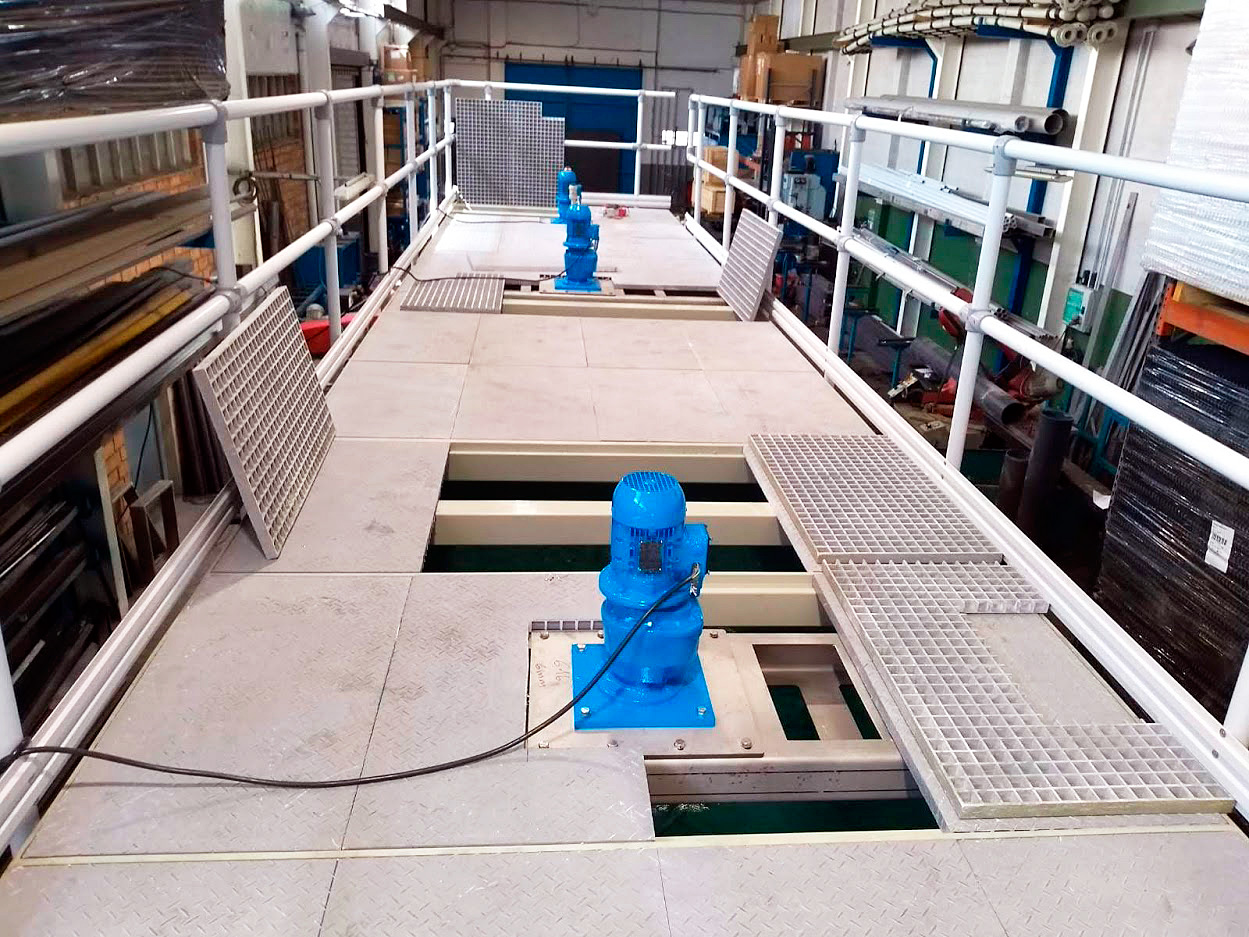

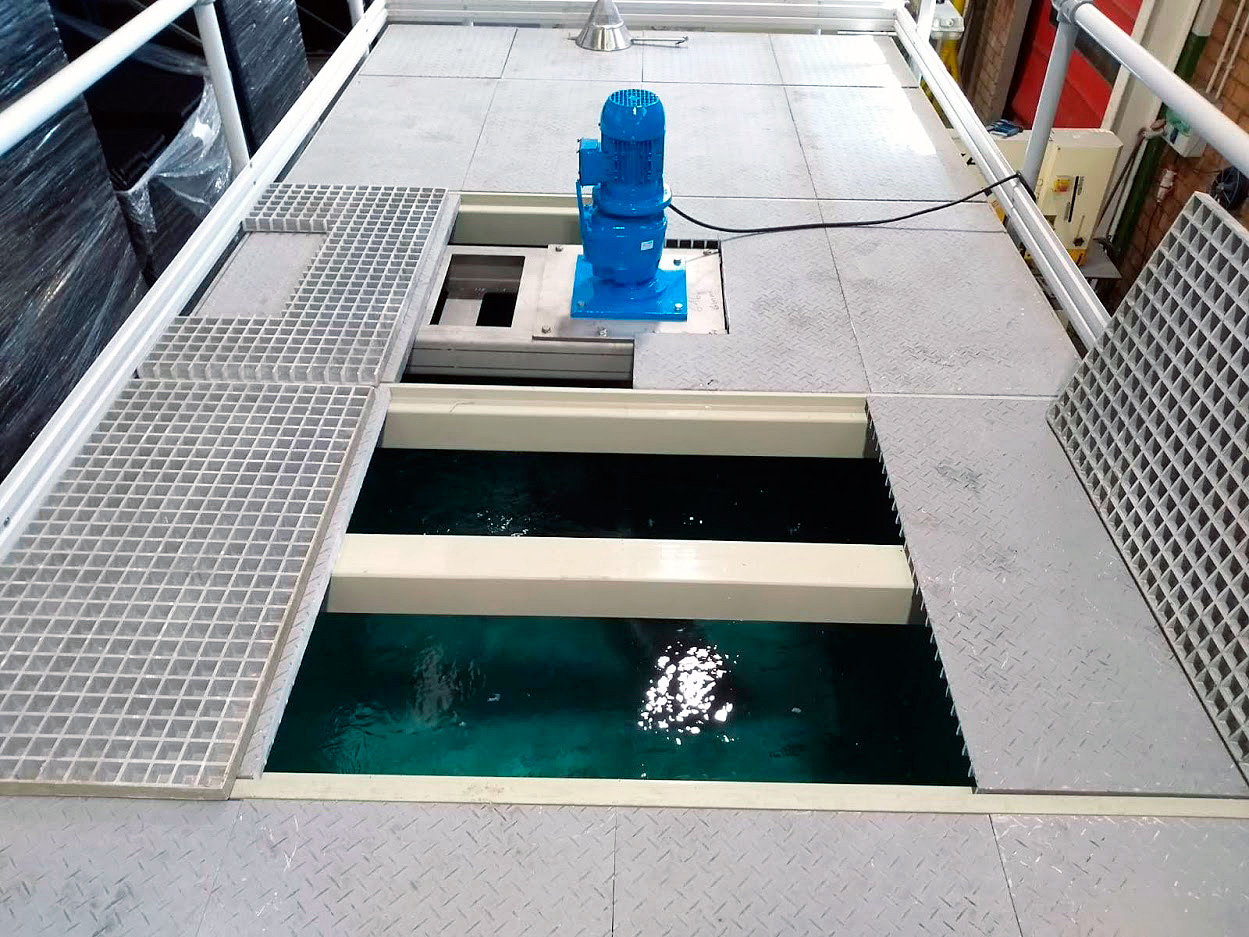

Each one of the treatment lines has one coagulation – flocculation tank with a volume of 43 m³, divided into three chambers each with a mixer calibrated for the correct homogenization and reaction to the dosed chemicals; and one compact clarifier with 35 m³ volume, based on the TecnoTec H80 lamellar technology that guarantees maximum sludge settling performance. With the supply of the water line tanks, three 3,5 m diameter and 30 m³ capacity sludge thickeners have also been supplied to process the resulting sludge byproduct of the water line.

Taking into consideration the residual effluent salinity, the tanks were manufactured in Polypropylene, and the mixers impeller and shaft supplied in Stainless Steel Super Duplex grade. The TecnoTec H80 lamella technology used is also made of Polypropylene, drinking water grade and NSF-std61 certified. The thickeners supplied are made of GRP.

For effective maintenance of the supplied equipment and an adequate process supervision, the water line tanks supplied have been equipped with walkable anti slippery tramex type covers, perimeter handrail and inclined access ladders, all made of GRP. The thickeners come with a fixed cover and manhole, perimeter handrail and vertical ladder, all made of GRP.

Once more, TecnoConverting excels with its potential as engineering office with the system concept and integration reaching maximum performance; and as manufacturer of high yield and quality compact equipment for harsh and extreme conditions.