TecnoConverting performs the renovation of the lamellar decantation at the WWTP GIRONA.

posted in News by TecnoConverting

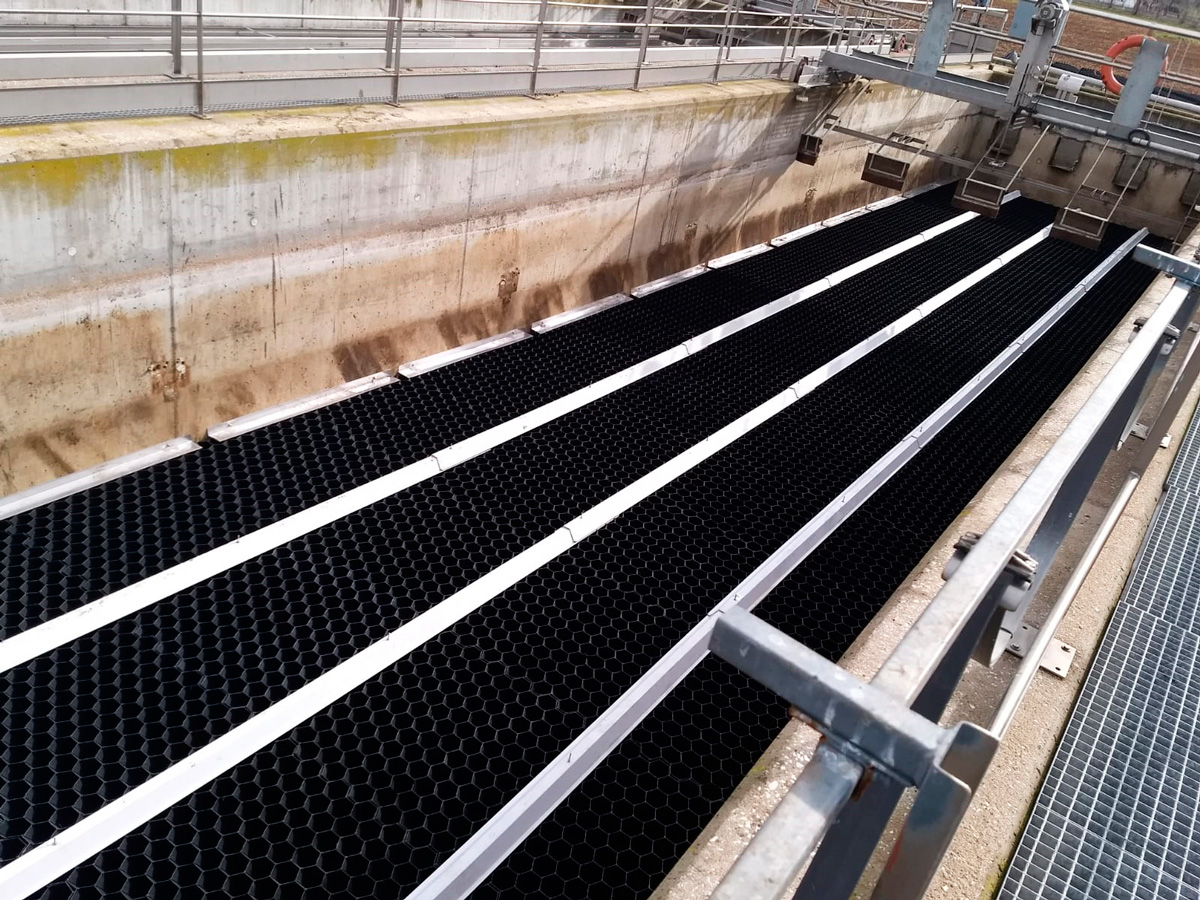

TecnoConverting Engineering has been awarded the public tender for the renovation of two primary lamella decantation lines of Girona´s WWTP. The project consists of the lamellae reposition, specifically, the support structure and lamella modules, as well as the restoration of the Thomson trough clarified effluent launders.

The chosen lamella technology for this project has been the PVC hexagonal TecnoTec H80, with a projected surface of 8,20 m²/m³ (the highest of its kind in the market), thus securing the maximum performance of the settler in terms of flow and solid retention capacity, combining it with the lowest clogging risk due to its very high hydraulic diameter (82 mm). This last factor is considered critical since it´s a primary decanter placed after the raw water pretreatment. The lamellae have been equipped with TecnoConverting proven and reliable SAF anti-flotation system.

The WWTP Girona lamella decanters are 19 meters long, 4,25 meters wide and 7 meters in depth, and a treatment capacity of one thousand cubic meters per hour (1.000 m³/h). The implantation of TecnoConverting´s TecnoTec H80 lamella technology allowed to reduce the work speed (Hazen) of the overhauled decanters, and also securing a very tight value in work condition with a peak flow with one decanters out of service, which is equivalent to a max. flow on one decanter of 1.500 m³/h.

As usual, TecnoConverting Engineering technical office performed the process and structure calculations to secure the system to withstand up to 80% mud clogging and guaranteeing the decanters performance as well as the adequate lamella support to avoid collapse or flotation situations. TecnoConverting also optimized the lamella and Thomson trough clarified effluent launders installation levels so as to secure uniform performance, a problem detected in the previous lamella.

All installation has been performed by TecnoConverting Engineering´s specialized team of technicians and supervised by our Technical Office, thus guaranteeing maximum quality in the installation.