TecnoConverting optimizes Sant Feliu’s WTP with Strongest Scrapers

posted in News by TecnoConverting

Sant Feliu de Llobregat’s wastewater treatment plant processes a daily flow of 72,000m³ and serves several populations in the metropolitan area of Barcelona.

TecnoConverting Engineering replaces three longitudinal rail bridges with high-strength rectangular Strongest scrapers at Sant Feliu de Llobregat WWTP

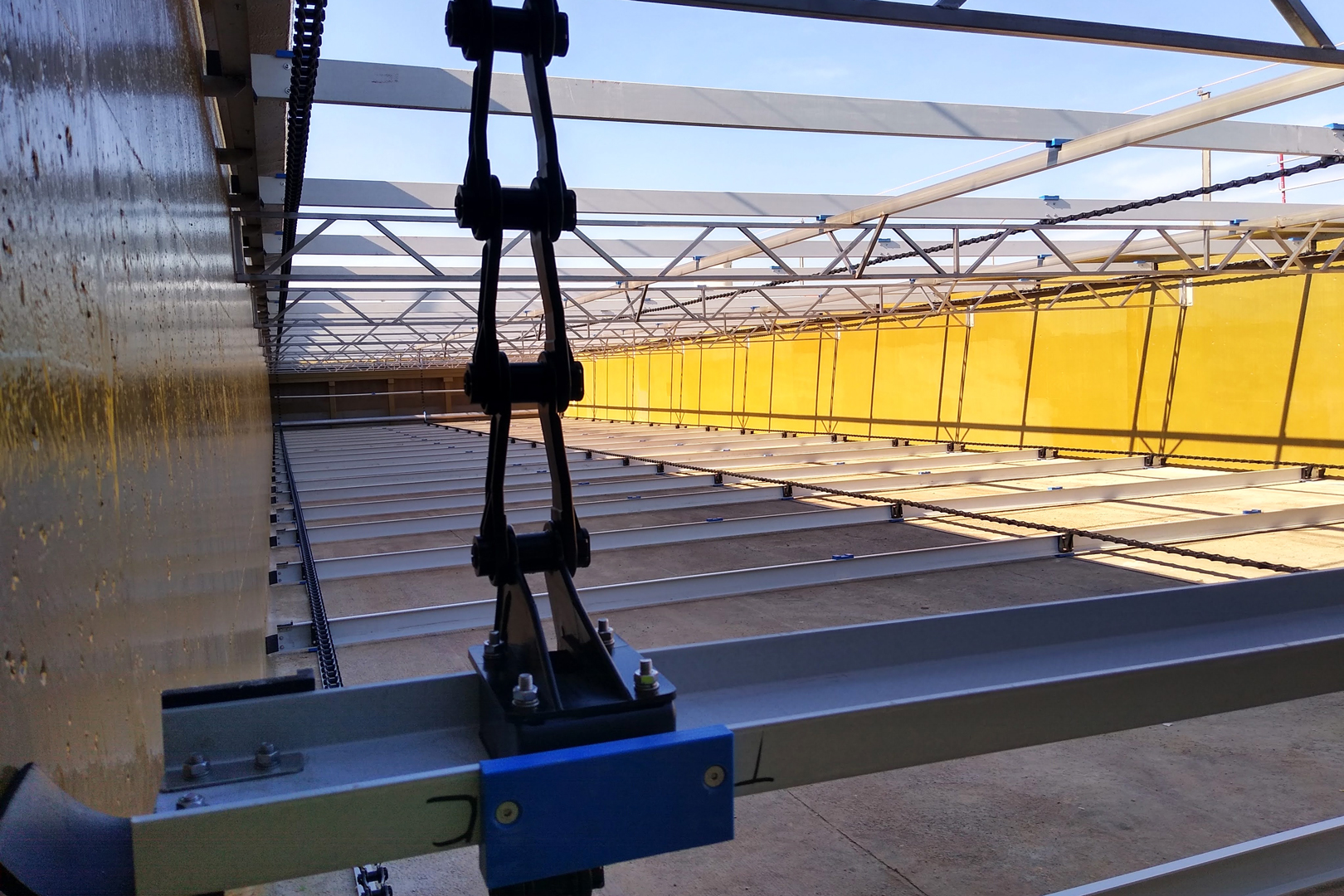

After pretreatment, as primary treatment, it consists of 3 rectangular settlers, where the sludge and floatable extraction system was carried out with 3 longitudinal rail bridges, each 15 meters wide for a collection length of 60 meters.

Due to the typical problems associated with such large longitudinal rail bridges, such as corrosion over time and the impact on the concrete of the running channels where the bridge passes due to the equipment’s significant weight, the property decided to replace them with more advanced technology to eliminate all the previous issues.

The existing longitudinal rail bridges were substituted with 4-axis rectangular scrapers. In this system, these units first bring all settling solids to the collection well. With the return of the upper blades, it is used to collect and drag floating particles to the tubular skimmer located on the opposite side of sludge collection.

The particularity of this project is the width of the settlers, which were 15 meters wide with a length of 60 meters. Typically, the majority of rectangular scrapers available on the market are standard for widths of 12 meters. In this case, TecnoConverting Engineering performs all the structural calculations for the sizing of the drive shafts, drag blades, and traction chains. This allowed us to design stronger scrapers by adding a central chain to ensure greater rigidity of the blades with that width. It is noteworthy that the equipment comes equipped with 2 safety systems: the parallelism detector, which stops the equipment if the blades are working misaligned, and the electronic torque limiter, which stops the equipment if any element gets trapped in the collection system.

It is crucial to emphasize the increased performance in primary sedimentation and the increase in sludge concentration achieved with these new Strongest scrapers. This results in much thicker sludge with less water content. The reason for this performance increase is that, with the existing scrapers, the rail bridge had to drag the accumulated sludge along the entire length of the settler (60 meters), causing disturbance of the settled sludge in its path. Similarly, due to the time it took for the existing rail bridge to go back and forth from the sludge collection well, the number of sediments deposited in the well was lower, reducing the concentration of accumulated sludge and resulting in a lower-quality sludge due to the high-water content.

With the newly installed Strongest scrapers, which have collecting blades every 3 meters, the collection of sludge and floatables becomes much more efficient. Solids are continuously deposited in the collection wells and floatables in the upper skimmer. As a result, the daily purges need to be increased due to the increased settled sludge during the same period of time.

Another advantage of using Strongest rectangular scrapers is the possibility of installing lamellar modules in the future, potentially increasing the capacity of the existing primary settlers up to 4 times.

The high-strength Strongest rectangular scrapers are manufactured in plastic material, except for the shafts, which are made according to the type of water to be treated, either in stainless steel or super duplex steel. The chains are made of polyacetal resin (POM) and are standardized to the NCS-720 model, allowing them to be interchangeable with different brands of scrapers present in the international market.

The Strongest rectangular scrapers are designed and manufactured entirely at TecnoConverting’s facilities in Sant Fruitós de Bages (Barcelona, Spain), and the assembly is carried out by the company’s own team of technicians, ensuring the proper installation, assembly, and operation of the supplied equipment.